Aircraft engine failure

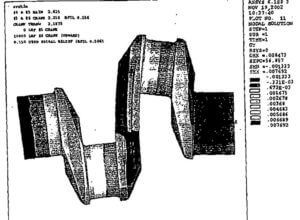

When a number of small airplanes experienced engine crankshaft failure and crashed, the engine manufacturer placed the blame on the company that made the crankshaft forgings. The FAA agreed.

In the midst of a worldwide recall of the affected engines, Edison Engineering was hired by attorneys representing the forging company to look at the allegations made by the engine manufacturer and FAA. They also wanted us to help them better understand the role the engines’ design may have played in the failures.

Our technical investigation demonstrated that the problem was a defective design of the crankshaft, not poor quality control in the forging factory. We discovered the manufacturer had never measured the relevant stresses the crankshafts were subjected to, relying solely on theoretical analysis. When measured, the actual stresses turned out to be much higher than the manufacturer stated. The higher stresses meant that the crankshafts lacked a sufficient safety margin between the stresses experienced during operation and the capacity of the crankshaft material.

The Result: Following eight weeks of trial during which we presented the results of our investigation, the jury agreed with our conclusions, finding design defects to be the sole cause of the engine failures and awarding our client over $96 million in damages. The liability portion of the verdict was upheld by the Supreme Court of Texas, nullifying a $186 million counterclaim by the engine manufacturer.

Services

Product/Machine Design Analysis

- Mechanical engineering & product design evaluation

- Testing and measurement

- Modeling, animation & data visualization